Dehumidifier Heat Pipes in Air Conditioning

- Made with high quality copper tubes for better heat transfer, reliability, and durability

- Highest heat transfer efficiency

- Low air pressure drop

- Tremendous increase in moisture removal capacity

- Lower supply air relative humidity

- Drier supply air

- Load reduction

- Replaces reheat

- Passive operation

- Requires only periodic cleaning

- Rapid ROI

- HPT factory, site or customer facility install

- ETL Listed

- Controllable

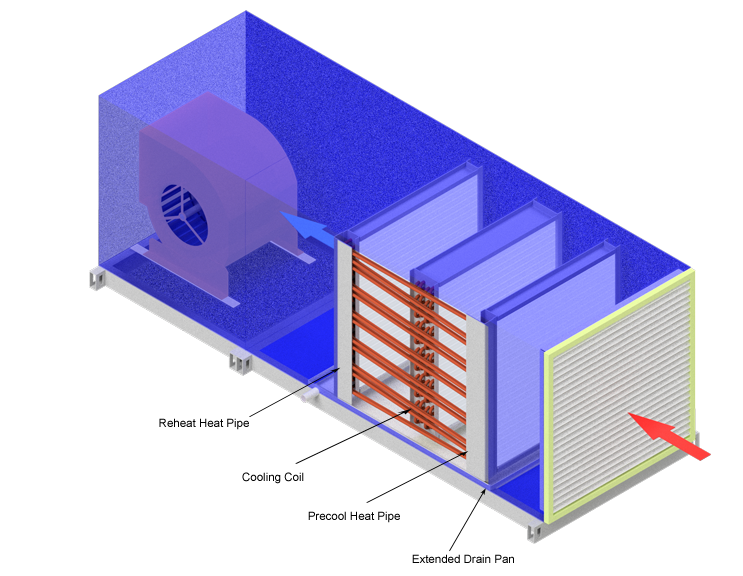

Typical Installation of a Wrap-Around Heat Pipe in an Air Handling Unit

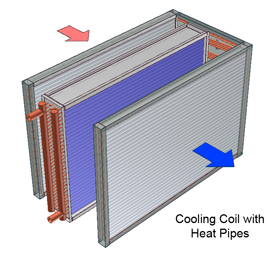

HPT dehumidifier Heat Pipes are usually installed in A/C units in a ”wrap-around” configuration. The first Heat Pipe module precools the entering air before it goes through the cooling coil. The precooled air then approaches the cooling coil at a lower temperature, allowing it to be overcooled by the cooling coil before being reheated by the second Heat Pipe module. The function of the Heat Pipe is performed passively without any mechanical moving parts. The Heat Pipe is activated by the temperature difference between the air entering the precool Heat Pipe and the air leaving the cooling coil.

Dehumidifier Heat Pipes can be installed around chilled water cooling coils as well as direct expansion (DX) cooling coils.

Methods of Installation

Factory Installed Wrap-Around Dehumidifier Heat Pipes - DHP-F™

NEW: A/C units are shipped by the manufacturer/contractor to the HPT facility in Tampa, Florida where they are factory retrofitted and then shipped to the final destination.

Site Installed Wrap-Around Dehumidifier Heat Pipes - DHP-S™

Units are retrofitted on site by HPT Heat Pipe trained technicians. Air conditioning units are site inspected with all measurements taken; Heat Pipes are then designed and built to fit. A site installation crew from HPT is sent to install the Heat Pipes. Heat Pipes have been site installed by this method in many locations inside the United States, including Hawaii, as well as the Caribbean, Asia, and South America.

U-Frame Wrap-Around Dehumidifier Heat Pipes - DHP-U™

U-Frame Heat Pipes are made-to-fit. They are designed for installation in an air handler or A/C unit at an equipment manufacturer’s facility. These are ideal units for installation into custom or configured air handlers.

Vertical Tubes Wrap-Around Dehumidifier Heat Pipes - DHP-V™

Vertical Tubes Wrap-Around Dehumidifier Heat Pipes are made-to-fit units designed either for site installation, installation at the HPT facility in Tampa, or at an OEM facility. These are ideal units for medium to large air handlers with varying reheat requirement. For best results, the reheat side of the system is elevated above the precool section.

Installation Requirements

A typical two-row Heat Pipe installation system (2 rows precooling, 2 rows reheating) requires 4" of space on both sides of the cooling coil. The Heat Pipes are typically mounted on both sides of the cooling coil. If required, and where space is available, Heat Pipes can be mounted in access sections provided by the manufacturer of the A/C unit or air hander.

One-row systems require approximately 2.25" minimum of space on both sides of the cooling coil.

Two-row systems require 3.25" on both sides. Three-row systems require 4.25" on both sides. Four-row Heat Pipe systems require 5.5" on both sides of the cooling coil, and so on.

For OEM installation, HPT will ship DHP-U™ sections to the air hander manufacture. The AHU needs to be designed to allow for the DHP-U™ retrofit . Besides needing to have space before and after cooling to install the heat pipes’ precool section and reheat sections, room is also needed at the back end of the cooling coil to allow for the encased connecting tubes. This space varies depending on number of rows and if controllable or not. Refer to HPT online selection software SelectPlus™ drawings for exact dimensions.

When considering fitting Heat Pipes into a unit, keep in mind the following:

1) Site Installation

Since Heat Pipe connecting tubes are always at the back end of the cooling coil (the end of the cooling coil that does not have manifolds, see diagram to the right), there must be room at that end for installation of connecting tubes, and also room between the A/C unit and the nearest object next to it to allow for technicians to work on the connecting tubes, evacuate, and charge. and for future maintenance on valves if the system is controllable.

2) Factory Installation

As in site Installation, controllable Heat Pipes need extra room for wiring and solenoid valve servicing after the A/C unit is installed on-site. The non-controllable Heat Pipes have no moving parts on the connecting tubes end. Access room to that end is recommended but not critical.

3) Airflow Direction

Airflow direction is critical for heat pipe installation and must be indicated on units to be retrofitted at the factory. Heat Pipes will not work with a wrong airflow direction. This is even more critical for DHP-U™ since it is a finished unit and will be installed into AHU directly at a customer’s facility.

4) Condensate Management

Precool section of the DHP™ can and will condense moisture. Therefore provisions of moisture capture and drainage have to be taken into account for all DHP™ installations. It is also recommended that the reheat heat pipes section is installed over a drain pan for cleaning purposes.

Types of Units That Can Be Fitted with Heat Pipes

Wrap-around dehumidifier Heat Pipes can be installed in almost any air handler or A/C unit. HPT has extensive Heat Pipe installation experience with equipment manufactured by Carrier, Lennox, Daikin, Trane, JCI, Addison, TMI, Air Enterprises, Seasons-4, Haakon, Annexair, Venmar and many others. If in doubt, check with your local HPT representative or with the HPT’s main office for installation requirements in specific units.

Below is a sample of units that can be fitted with wraparounds.