Recently Shipped - HPT Provides Several Large Heat Recovery Heat Pipes to an American Multinational Consumer Goods Company

Heat Pipe Technology recently shipped 6 large energy-recovery heat pipes to an American multinational consumer goods company in Cincinnati, Ohio. Its product line includes major brand name cleaning agents and personal care products. This project was part of a $300 million expansion to a facility consisting of chemistry and biology research laboratories, a process plant, and lecture halls.

H.C. Nye, a HPT representative, came across this opportunity and worked with an engineer from the east coast to design the HVAC system that included heat pipes. Heat pipes were chosen because of the need for no cross-contamination that other energy recovery devices cannot provide. For this reason, the heat pipe units contained a 3" foam-filled center partition.

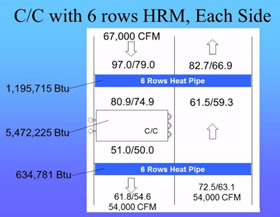

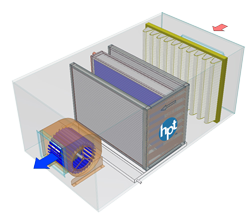

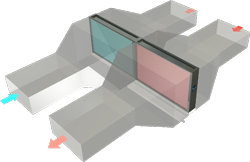

The heat pipes will be installed into three large custom AHU's totaling 67,000 CFM's. Each AHU will utilize a 6-row heat pipe to pre-treat 100% OA during winter and summer seasons, and a second 6-row heat pipe to reheat conditioned air during summer season. The proposed layout of the AHU's and heat pipes is represented by the image below.

The typical heat pipe unit size had a finned height of 131.25" and a finned length of 200". With the addition of the HRM™'s, the estimated cooling load reduction at design is 100 tons, and the expected heating load reduction is 1,387 MBTU. Economic analysis showed an estimated average annual savings of $52,500/year per heat pipe.

Webinar - The Wonderful World of Heat Pipes And How They Can Be Effectively Utilized to Meet Energy Code

Drew Elsberry, Regional Sales Manager for HPT, recently gave a webinar on our continuing series for the Wonderful World of Heat Pipes. The webinar covered the following topics:

- ASHRAE Standard 90.1 - Energy Code

- How heat pipes can meet code requirements

- How wrap-around heat pipes compare to ERV's

- How control valves offer more than just controllability.

*NEW* White Paper: Controlling Wrap-Around Heat Pipes for Systems with Strict Space Humidity Requirements

Michael Davis, PE, LEED Green Associate.

Michael is a Sales Engineer with Flow Tech Inc, a representative agency located in Connecticut. Michael works with owners and the consulting engineering community to find solutions for some of the more technically complex systems in his region covering all of Connecticut, and parts of Massachusetts and New York.

The paper provides background on wrap-around heat pipes, how they function, challenges that strict humidity requirements bring, and examples of how to overcome these challenges. The white paper gained the attention of a major trade publication and was featured in their online section.

May 2016 - In This Issue:

Recently Shipped - HPT Provides Several Large Heat Recovery Heat Pipes to a Major Consumer Goods Company

Webinar - The Wonderful World of Heat Pipes

*NEW* White Paper: Controlling Wrap-Around Heat Pipes for Systems with Strict Space Humidity Requirements

Providing Energy Saving Solutions to The World Market

Our knowledgeable, worldwide rep network will work with you to implement our technology for both dehumidification and energy recovery applications

Find a representative in your area.

This newsletter is a service of HPT, Inc. It is meant to familiarize users with heat pipe technology, and how to select heat pipe systems using SelectPlus™ design software.

Click here to read more about the DHP™ Series

Click here to read more about the HRM™ Series and our *NEW* HRM-Z™ model

NEW!!!

Follow us on

![]()

![]()

![]()

Missed a newsletter? Visit our archives

Want to learn more about our technology? Visit our website

Not a SelectPlus User? Click here