Indoor Agricultural Controlled Environment

With the accelerated growth of cannabis facilities in parts of the US and all across Canada, HVAC design engineers are challenged to come up with energy and cost-efficient systems that simulate the optimal indoor growth environment.

Grow facilities need to deal with varying conditions caused by day and night cycles while keeping temperature and humidity levels under control. Night conditions (lights off) present a special challenge due to the lack of sensible heat (dry heat), while latent heat (moisture in the air) load remains more or less the same. HVAC Design engineers opt for adding either expensive standalone dehumidifiers or very costly reheat after the cooling coil for night conditions. This reheat essentially ads sensible heat to the space to compensate for the missing sensible load when lights are off. In doing so, cooling systems will continue to run, thus removing moisture from the air to maintain relative humidity levels at 50% and a dry bulb temperature of 75°F. Since night conditions represent at least 12 hours of the daily cycle, active reheat or standalone dehumidifiers can add a significant cost to the operation. In critical applications like these, where reheat is used, wrap-around heat pipes can help reduce the cost of cooling and reheating and generate significant energy savings year-round. Controllable heat pipes should be the type considered so they can be turned off during the day cycle when lights are on, and turned on during the night cycle to provide needed reheat.

Passive wrap-around heat pipes precool and reheat the air without the use of pumps or compressors. They are comprised of a precool coil and a reheat coil where the precool coil is located upstream of the cooling coil, thus reducing the load on the cooling coil allowing possible downsizing of cooling equipment. The wrap-around then uses its reheat coil, downstream of the cooling coil, to return the heat captured from the precool side back into the airstream to reduce or eliminate the need for reheat. Wrap-around heat pipes can also be fitted with control valves to stage the performance during hours where less or no reheat is needed.

An analysis of a recent project with 12,000 CFM of air with an entering air temperature of 80°F DB and cooling coil leaving air temperature of 45°F, showed significant energy savings when wrap-around heat pipes were employed. With a 3-row wrap-around system sized for 440 FPM air velocity, the entering air temperature was reduced to 70°F DB before entering the cooling coil. This resulted in a 17% reduction in cooling load, which equates to 12 tons of precooling performed by the heat pipe. After the cooling coil cools the air further down to the setpoint, the heat pipes' reheat coil raises the temperature to 55°F DB which equates to 144,000 Btu/hr (42 KWh) of site recovered reheat. In the above example, paybacks can be three years or less.

Advantages of Using HPT Heat Pipes in Indoor Controlled Agricultural Environment:

- Passive Dehumidification

- Controllable: Can be turned on or off as needed

- Possible A/C load reduction

- Reduction or elimination of expensive reheat

- RELIABLE – No moving parts to fail

- Small footprint, less space taken

- Can be added to new or existing systems

- Can be fitted to air handlers of all shapes and makes

- Many refrigerant circuits provide added REDUNDANCY

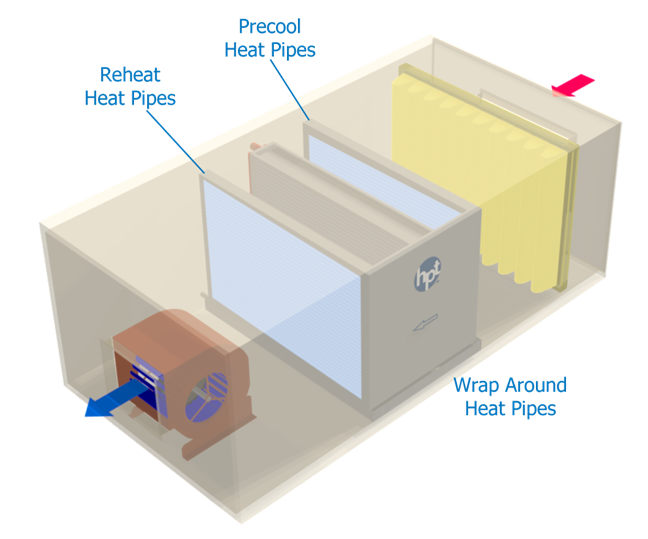

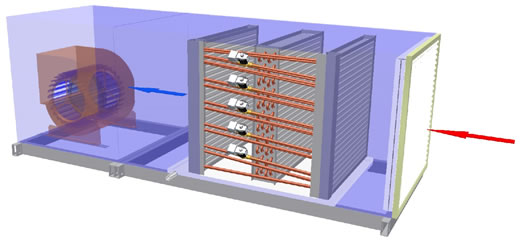

Typical Layout of an Air Handler with Wrap-Around Heat Pipes

Illustration above shows a warap around heat pipe system with multiple circuits and solenoid valves for controllability. Control valves can be incorporated in factory installs as well as U-Frames like the product below. Valves can be grouped in upto 4 stages which can be turned off to reduce or eliminate the heat pipe effect. This usually happens when sensible loads are highest. In grow facilities, control valves would be energized to reduce or disable the heat pipe effect during daylight conditions when sensible load is high.

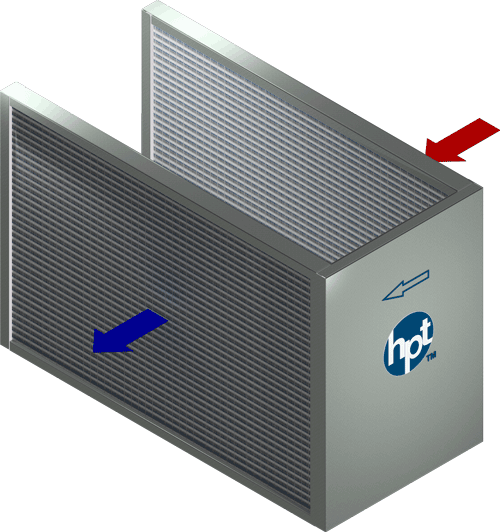

Illustration above shows a U-Frame. A very versatile product popular with OEMs. The wrap around U-Frames are built to fit int air handlers and other A/C systems. U-Frames can be built with or without the controllability options. Similar or other heat pipe systems, options include copper fins, coatings and stainless steel sheet metal.