Precool-Reheat

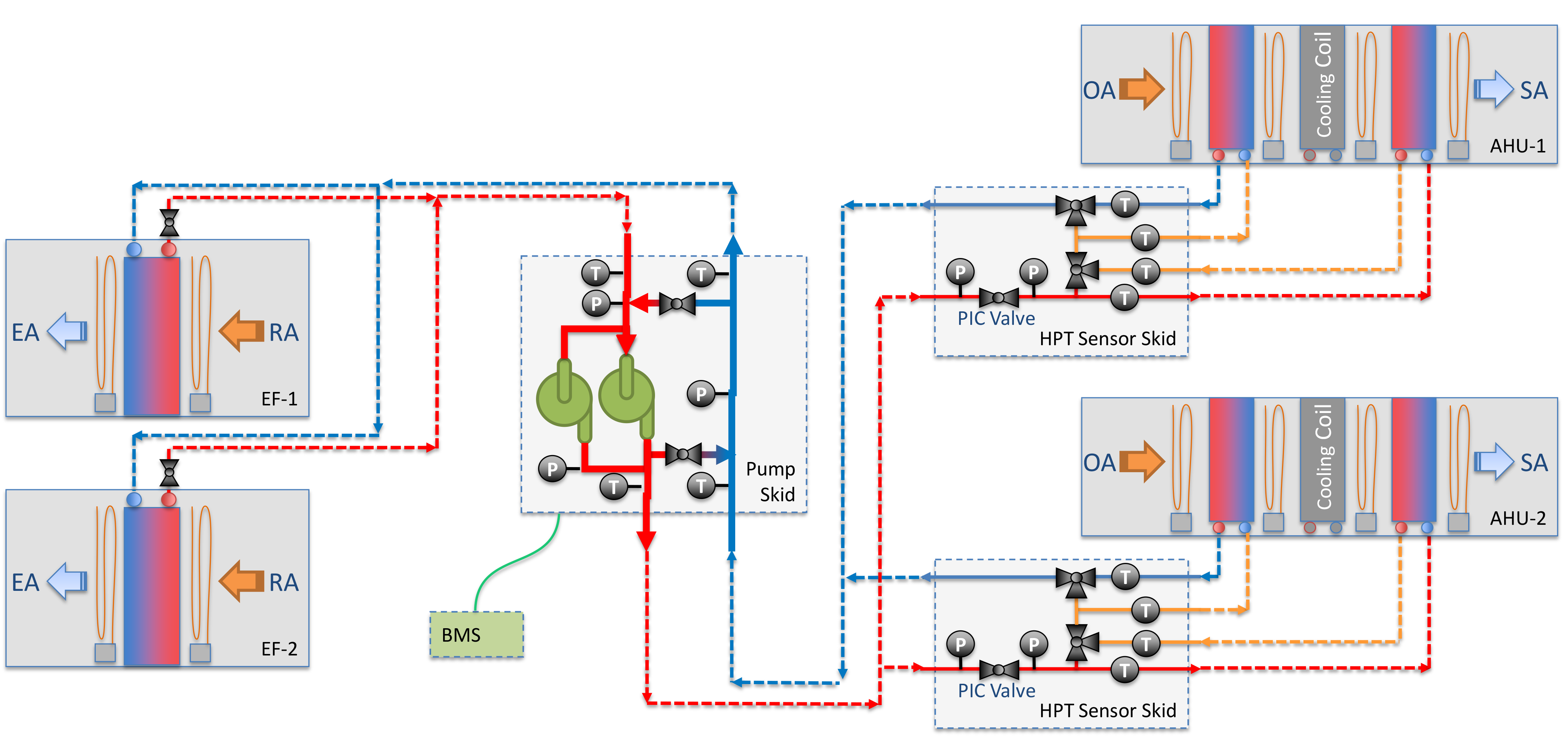

When the SMART Water Glycol System is equipped with Precool-Reheat capabilities, the energy recovery skid gains the ability to precool the incoming outside air while also supplying reheat downstream of the cooling coil. Precool-Reheat is an innovative recovery solution that maximizes the use of waste heat and transforms the potential of a run-around glycol system.

Standard Energy Recovery

In a standard run-around energy recovery system without Precool-Reheat, the exhaust air temperature generally hovers around 75F in the summer. During cooling mode, the water leaving the exhaust energy recovery coil is usually cool enough to precondition/precool the outside air, and is supplied to a single energy recovery coil in the supply airstream, upstream of the cooling coil to precool the outside air. This reduces the load on the cooling equipment and is how most energy recovery systems operate during summer cooling.

Energy Recovery with Precool-Reheat

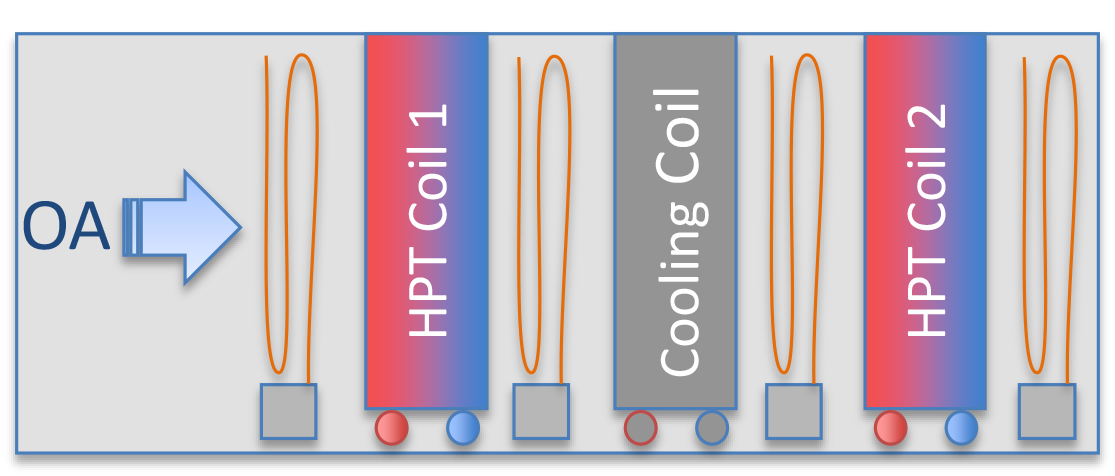

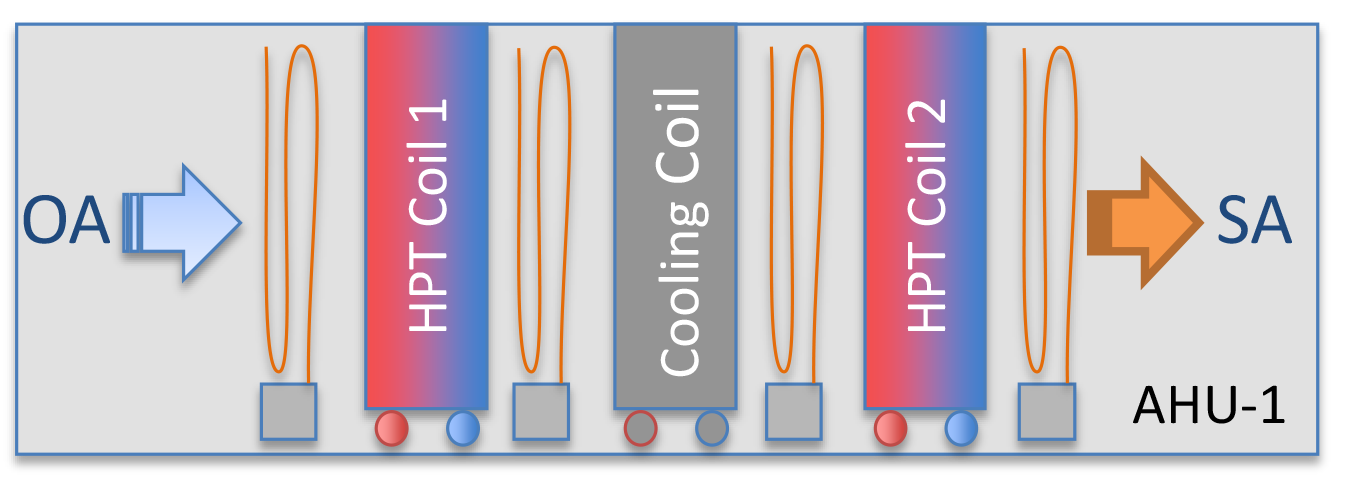

However, in a run-around system with Precool-Reheat configured, it is also recognized that the water leaving the exhaust energy recovery coil is generally warmer than the cooling coil leaving air temperature. Therefore, it can be utilized to provide reheat downstream of the cooling coil, tempering the supply air before being supplied to the space. For this reason, HPT splits its supply energy recovery coil into two coils – one coil upstream for precooling the outside air and another coil downstream of the cooling coil for reheat. Passing the water from the exhaust first through the downstream coil not only provides reheat but also lowers the temperature of the water further before being supplied to the upstream coil to precool the outside air.

Hardware/Configuration

A sensor skid, supplied by HPT, is used in each supply airstream with precool-reheat capacities. The sensor skid communicates back to the main pump skid and allows the leaving air temperature of both the precool and reheat coil to be controlled within 0.1 degrees of a user-defined setpoint. A total of 18 airstreams can be controlled simultaneously from the main pump skid via BACnet or Modbus protocol. This innovative approach to energy recovery reduces both the cooling and heat load on the HVAC equipment.