Wrap-Around Heat Pipes Applied to Indoor Grow Facilities

Growing Savings All Year Long

With the cannabis industry exploding in parts of the US and all across Canada, engineers are working toward designing energy and cost-efficient HVAC systems that simulate the optimal indoor growth environment. Grow facilities are tasked at simulating both day and night conditions in a 24-hour period. While keeping temperature and humidity levels under control is tough in this environment, night conditions present a special challenge due to the lack of sensible heat, yet latent heat load remains the same. Design engineers opt for adding very costly reheat for night conditions to maintain humidity at 50% RH and dry bulb above 65°F. And since night conditions represent at least 12 hours of the daily cycle, active reheat can add a significant cost to the operation. In critical applications like these, where dehumidification and reheat are used to control the relative humidity in the space, Heat Pipe Technology uses its wrap-around heat pipes to help reduce the energy cost of cooling and reheating equipment and generate tons of energy savings year round.

With the cannabis industry exploding in parts of the US and all across Canada, engineers are working toward designing energy and cost-efficient HVAC systems that simulate the optimal indoor growth environment. Grow facilities are tasked at simulating both day and night conditions in a 24-hour period. While keeping temperature and humidity levels under control is tough in this environment, night conditions present a special challenge due to the lack of sensible heat, yet latent heat load remains the same. Design engineers opt for adding very costly reheat for night conditions to maintain humidity at 50% RH and dry bulb above 65°F. And since night conditions represent at least 12 hours of the daily cycle, active reheat can add a significant cost to the operation. In critical applications like these, where dehumidification and reheat are used to control the relative humidity in the space, Heat Pipe Technology uses its wrap-around heat pipes to help reduce the energy cost of cooling and reheating equipment and generate tons of energy savings year round.

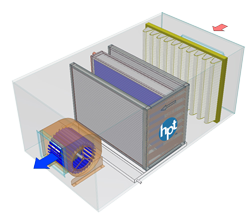

Passive wrap-around heat pipes precool and reheat the air without the use of pumps or compressors. Wrap-arounds use a precool coil upstream to reduce the load of the cooling coil and allow the cooling equipment to more easily reach its designed dew point temperature. The wrap-around then uses its reheat coil to return the heat captured back into the airstream and reduce or eliminate the need for auxiliary heating. Wrap-around heat pipes can also be fitted with control valves to stage the performance during hours where less or no reheat is needed.

The analysis of an actual 12,750 CFM system, with an entering air temperature of 80°F DB and cooling coil leaving air temperature of 45°F, revealed significant energy savings when wrap-around heat pipes were employed. With a 3-row wrap-around sized for 440 FPM, the entering air temperature was reduced to 70°F DB before entering the cooling coil. This resulted in a 17% reduction in cooling load, which equates to 12 tons of precooling performed by the heat pipe. After the cooling coil cools the air further down to the setpoint, the heat pipes' reheat coil raises the temperature to 55°F DB / 69% RH, which equates to 144,000 Btu/hr of site recovered reheat.

For more information, please contact us by email at info@heatpipe.com. You can also call our main business line at 813-470-4250.

Project Focus

Cross-Contamination Free Energy Recovery at Medical Manufacturing Facility in Utah

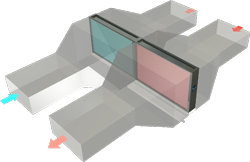

Heat Pipe Technology recently secured the second order of split-passive heat pipe systems for a large medical manufacturing facility in the Utah area. A few years back, HPT had already had two of its split-passive systems installed into two large air handling units totaling 47,000 CFM. The success of that project paved the way for the inclusion of heat pipes in the second phase. However, with the advancements in research and development at HPT's state of the art R&D facility, HPT started integrating face dampers along the top and bottom face of its split-passive heat pipe coils. The dampers functioned to redirect the flow of air through optimal sections of the coil that yield the most energy recovery. Using the dampers in this way provided an improvement in performance by 20 to 30%. The dampers can also be alternated into their reverse positions so that the improvements in performance are achieved in both summer and winter conditions. HPT first announced this new energy recovery product line in mid-2018 as the split passive HRM-V with Dynamic Seasonal Offset (DSO™).

Heat Pipe Technology recently secured the second order of split-passive heat pipe systems for a large medical manufacturing facility in the Utah area. A few years back, HPT had already had two of its split-passive systems installed into two large air handling units totaling 47,000 CFM. The success of that project paved the way for the inclusion of heat pipes in the second phase. However, with the advancements in research and development at HPT's state of the art R&D facility, HPT started integrating face dampers along the top and bottom face of its split-passive heat pipe coils. The dampers functioned to redirect the flow of air through optimal sections of the coil that yield the most energy recovery. Using the dampers in this way provided an improvement in performance by 20 to 30%. The dampers can also be alternated into their reverse positions so that the improvements in performance are achieved in both summer and winter conditions. HPT first announced this new energy recovery product line in mid-2018 as the split passive HRM-V with Dynamic Seasonal Offset (DSO™).

For the second phase of this project, HPT will be shipping a 6-row split-passive system equipped with integral face dampers for dual season enhanced recovery. The system will be installed into a 25,000 CFM air handling unit where it will pre-treat ventilation air during the summer and winter. The estimated cooling load reduction gained from using the split passive system at design condition is 17 tons, and the anticipated heating load reduction will be 700,000 Btu/hr.

If you would like to learn more about HPT's split-passive heat pipes, please contact us by email at info@heatpipe.com. You can also call our main business line at 813-470-4250 or click the link below.

Utilizing Energy Recovery Heat Pipes in Data Centers

The single largest contributor to power consumption in data centers is the cooling system. On average, roughly 40% of the total consumed power is due to cooling server rooms down to a suitable temperature year-round. Passive energy recovery heat pipes play a major role in reducing power consumption and enabling data centers to run at peak efficiency. Heat pipe energy recovery modules (HRMs) provide passive cooling to reduce loads and downsize the mechanical cooling system, whether Direct Expansion or Chilled Water.

Heat Pipe Technology's HRMs consist of copper tubes, aluminum fins, and a working fluid that changes phase passively to move heat. As air passes over the warm side (data center return air) of the heat pipe, the refrigerant vaporizes, absorbing energy, then travels to the cold side (outside air) where it condenses, releasing energy, and flows back to the warm side. This process occurs as long as outside air is cooler than data center air. This enables data center cooling without introducing outside air to the server room space. Additional cooling can be provided by evaporative cooling the outside air before the heat pipe for warmer days and direct mechanical cooling after the heat pipe in the return air stream for the warmest summer days.

To get a copy of our application paper on data centers, please contact us by email at info@heatpipe.com. You can also call our main business line at 813-470-4250.

Wrap-Around Heat Pipes (DHP)

Wrap-Around Heat Pipes (DHP)

Wrap-Around heat pipes can save energy and enhance dehumidification either by replacing or minimizing the expensive reheat, or by reducing the load on the cooling coil. To learn more about the features and benefits of this product, please follow the link below.

Side-by-side Energy Recovery (HRM)

HPT's Energy Recovery Heat Pipes are an economical, passive, and reliable energy recovery device capable of recovering energy during both heating and cooling seasons. To learn more about the features and benefits of this product, please follow the link below.

SelectPlus™ Design Software

HPT's powerful web-based selection software allows user 24/7 access to our product's performance, economic analysis, and more. Please click below to request an account.

AHRI Certified and ETL Listed

HPT is both AHRI certified to AHRI Std 1060 for our air-to-air heat exchangers and ETL Listed to UL Std 207 and CSA Std C22.2#140.3 for all of our existing products.

|

This newsletter is a service of HPT, Inc. It is meant to familiarize users with Heat Pipe Technology, and how to select heat pipe systems using SelectPlus™ design software. |